- Home

- >

- Preservation Archaeology Blog

- >

- Hands-On Archaeology: How to Build a Pithouse

Allen Denoyer, Archaeology Southwest, and Gary Owens, Huhugam Ki Museum, Salt River Pima-Maricopa Indian Community

(January 16, 2018)—In fall 2017, at Museum Director Gary Owens’s invitation, Allen Denoyer joined Gary’s team at the Huhugam Ki Museum at the Salt River Pima-Maricopa Indian Community to help build a new replica pithouse just outside of the museum. This is their account of the process.

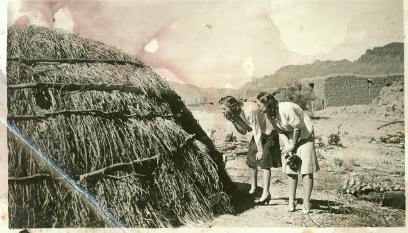

Allen: The replica dwelling pictured above was built a few years back. Because it just did not look right according to the community’s traditions, the museum planned to tear it down and reuse some of the materials to build a more accurate-looking version.

Gary: The house had been built by others, to the best of their ability, but what we eventually wanted to see was something that made us think, “Yeah, that’s what they described to me when I was little.”

In all, we estimated about 18 hours of digging and sifting to dig about 10–14” down. Community members did the excavation, which gave them a chance to see what was really in that mound of dirt—their past.

Allen: Gary and his crew dismantled the existing house and stockpiled its construction elements for use on the new house. They began excavation of the house pit on August 26. The excavated soil was loaded with ancient artifacts and modern trash, including glass and nails. The crew screened the dirt and collected the artifacts for later analysis.

There are several reasons to dig a house pit. First, it supplies the dirt needed for the roof and berm around the house pit edge. Second, the subterranean floor conveys thermal advantages: in the summer the house stays cooler, and in the winter it is easier to keep warm.

We began actual house construction on September 8. The four mesquite posts in this picture were recycled from the previous house, as they were still in good shape. We used bailing wire to tie the structural elements together. The long poles are pine poles recycled from a fence. On top, we laid cross pieces of willow and then one more long pine pole across the willow. This is the completed inner superstructure.

In these photos we are placing large willow uprights around the perimeter of the house and bending them over to the roof. The bands around the house parallel to the ground are made of bundled arrow weed wrapped with bailing wire. Gary came up with this technique and it worked quite well. Willow branches would also work well for this step.

Gary: Ours was once a riparian land that had a river run through it, but no longer. Our resources are very limited. We had to utilize all materials and make sure nothing went to waste. In some cases, we had to go and buy supplemental natural materials so that we wouldn’t take too much from the land at one time.

Gary: When the crew members were mixing mud in the wheelbarrow with the shovel, we tried to make it as moist as masa—a good spreading consistency. And we had heard that in order to make the earthen top, you start out lightly. Then when it rains, you add more dried dirt a bit at a time and let it build up. That way it does not get to top-heavy and list.

One thought on “Hands-On Archaeology: How to Build a Pithouse”

Comments are closed.

Concerning pit homes and ancient Pueblo peoples All the diagrams I see some people doing intricate work inside the house with the only source of light a cooking fire. From my experiences camping a cooking fire is pretty small and not made for light. We’re they using supplemental lighting devices like oil lamps or candles?