- Home

- >

- Preservation Archaeology Blog

- >

- Hands-On Archaeology: How to Use Lac, the Amazing,...

We hope you enjoy this post from our most prolific blogger, Allen Denoyer. Thanks for all the great posts, Allen!

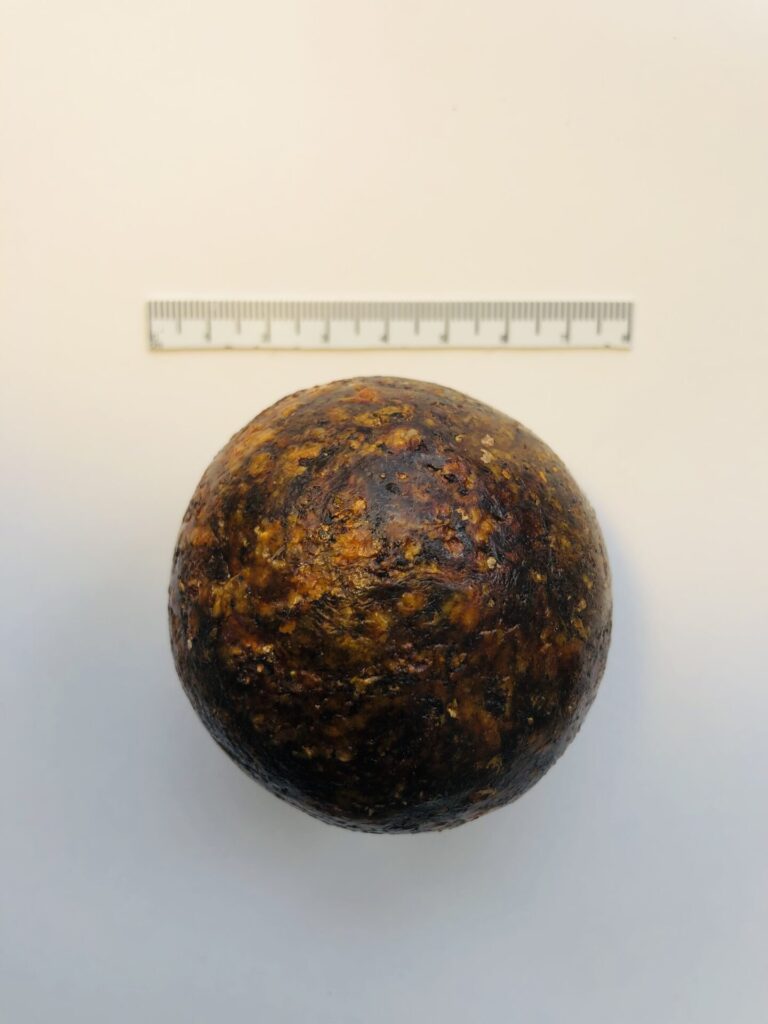

(August 29, 2025)—Earlier this year, I shared information about how to ethically harvest lac. Prior to that, conservator Marilen Pool wrote about lac use in the ancient Southwest. In this post, I want to show you some of the projects I’ve been doing involving lac. People did almost all of these things in the ancient and more recent past, and lac is still being used today.

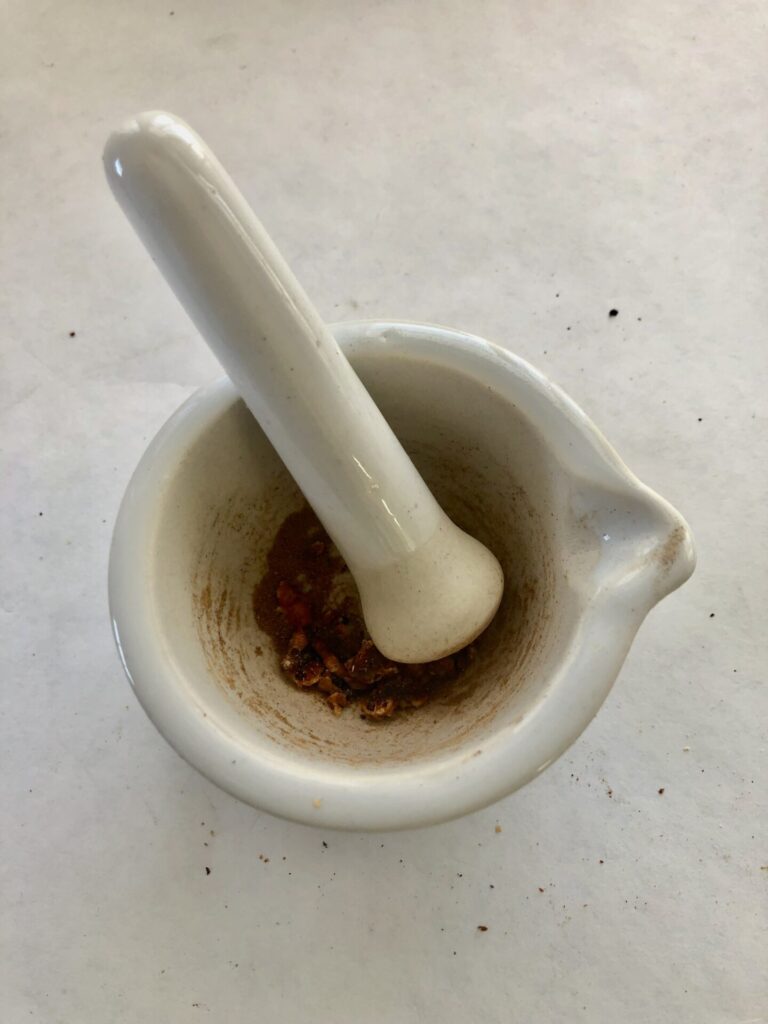

Let’s start with how I’m learning to process lac for use.

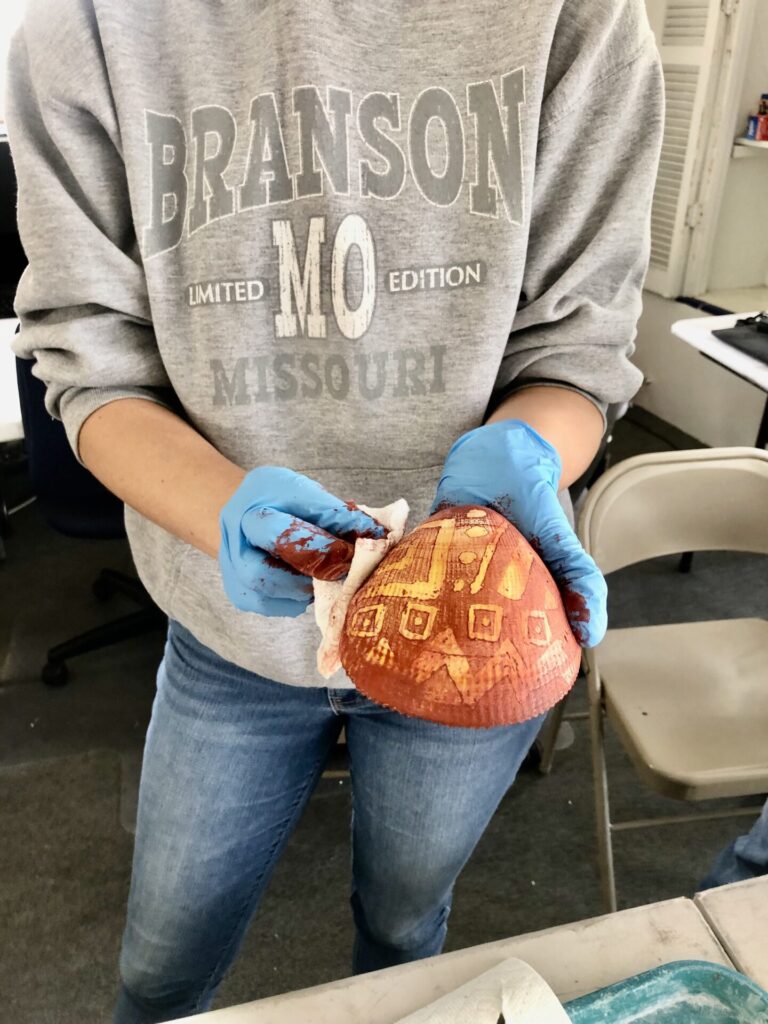

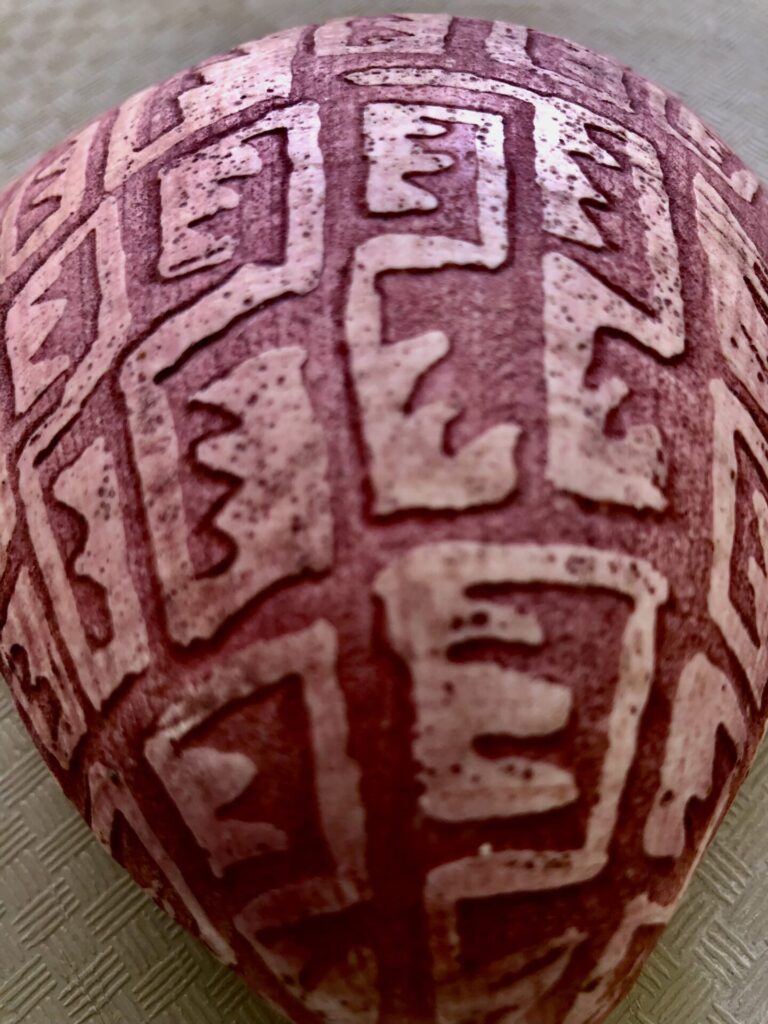

The next step is to clean away the lac paint with alcohol. Areas covered by the lac paint will have protected the shell surface, and they remain glossy and smooth.

I like to then stain my shells with mineral pigments mixed with lac paint or use organic dyes purely of lac or of cochineal.

Another use of lac I’m exploring is in making composite beads. From a Mimbres archaeological culture site in New Mexico, we have evidence of how people there made composite beads. There is no direct evidence they used lac to do this, but I thought I’d try it.

The first step is to thin out (by grinding) a slab of pretty stone. Then, incise notches to create strips of stone. Snap off the strips, and then snap them into roughly square sections (bead blanks).